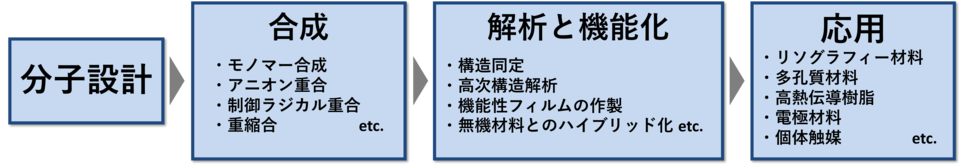

Research in the Hayakawa Laboratory focuses on the development of functional materials based on polymer synthesis techniques. Among various research themes, particular emphasis is placed on utilizing the self-assembly of block copolymers for the development of ultrafine processing technologies and porous materials. By actively leveraging relatively weak intermolecular interactions, such as hydrogen bonding, coordination bonding, van der Waals forces, and hydrophilic-hydrophobic interactions, it is possible to create precise nanostructures with controlled molecular arrangement and orientation, crystalline-liquid crystal structures, and phase-separated structures on the nanoscale. By maximizing the inherent potential of molecules to self-assemble, the lab engages in everything from molecular structure design and precision polymerization to controlling higher-order structures, successfully developing tailor-made materials unparalleled in other fields.

If you feel that the explanation above is honestly difficult to understand, don’t worry! Don’t overthink it! Once you see the fascinating process of a compound you designed and synthesized self-assembling right before your eyes, you’ll immediately be captivated by the allure of self-assembled materials. Let’s conduct research together!

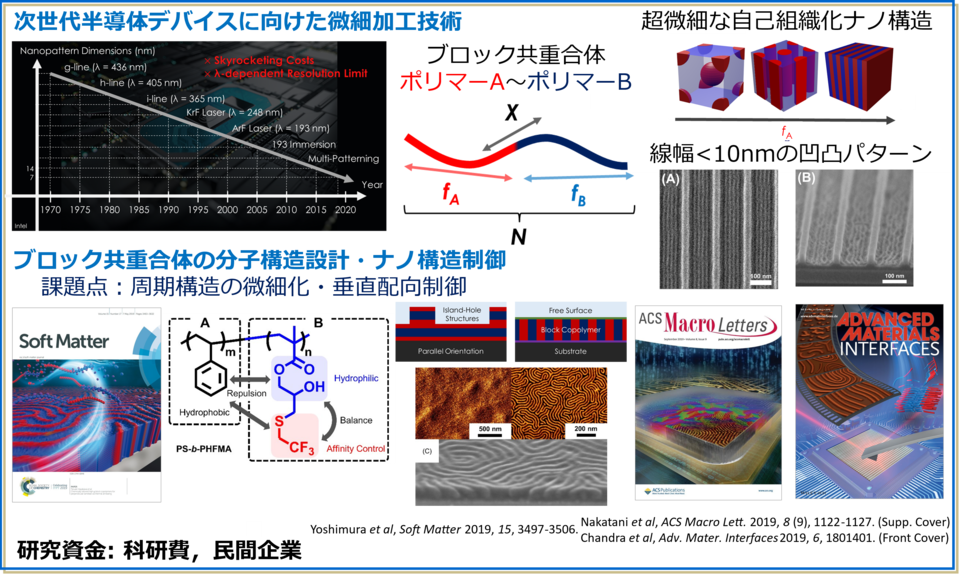

Research 1. Synthesis of High-χ Block Copolymers and Next-Generation Lithography

The miniaturization and enhanced functionality of electronic devices such as computers and smartphones rely on the progress of semiconductor microlithography (lithography) technologies. Therefore, advancing new lithographic techniques capable of high-resolution (high-definition) and ultrafine processing is crucial for the development of organic polymeric materials. However, current mainstream lithography methods are approaching the limits of resolution due to cost and technical constraints.

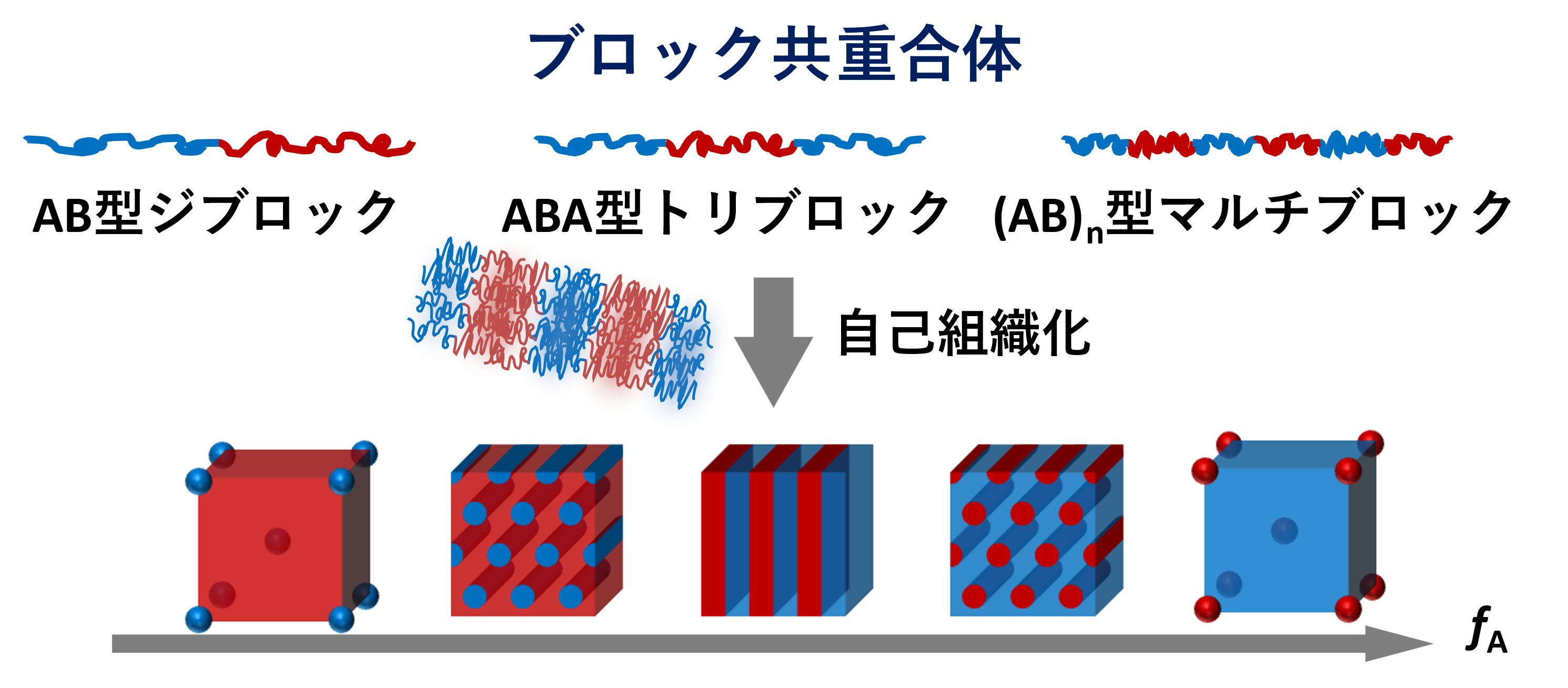

Recently, a novel lithography technique that utilizes the self-assembly of high molecular weight block copolymers to create periodic structures has gained attention. This technique, called “block copolymer lithography,” has a significant connection to improving semiconductor microlithography. Block copolymers consist of polymers with structurally distinct blocks at each end. These polymers can self-assemble into nanoscale periodic structures (domains) corresponding to the size of polymer chains, typically in the range of 10 to 50 nm. This phenomenon is known as microphase separation.

Microphase separation results in various morphologies such as sphere, hexagonally packed cylinder, and lamellar structures. These distinctive features of block copolymers are being applied in creating fine patterns on semiconductor substrates, forming ultrafine patterns at the single-nanometer scale. By combining block copolymers designed and synthesized in-house with lithography techniques, we are pursuing the creation of ultra-high-resolution circuit patterns for the next generation.

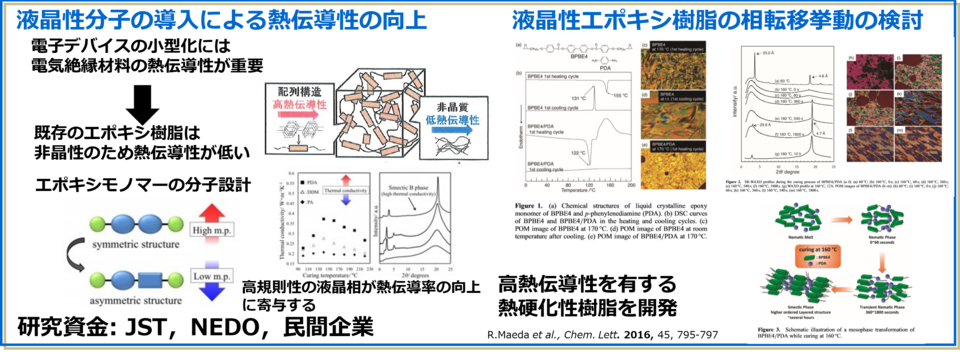

Research 2. Development of Insulating, High-Thermal-Conductivity Epoxy Adhesives

With the increasing performance of electronic devices, efficiently dissipating excessive heat generated in mounted components has become a critical challenge. However, the electrically insulating materials used to bond substrates to semiconductors inside devices, such as epoxy resins, have extremely low thermal conductivities (0.1–0.2 W/m·K), creating a bottleneck in heat dissipation.

To address this issue, we are conducting research aimed at developing high-thermal-conductivity epoxy resins by introducing mesogenic structures into the epoxy resin backbone, thereby imparting liquid crystallinity to the material.

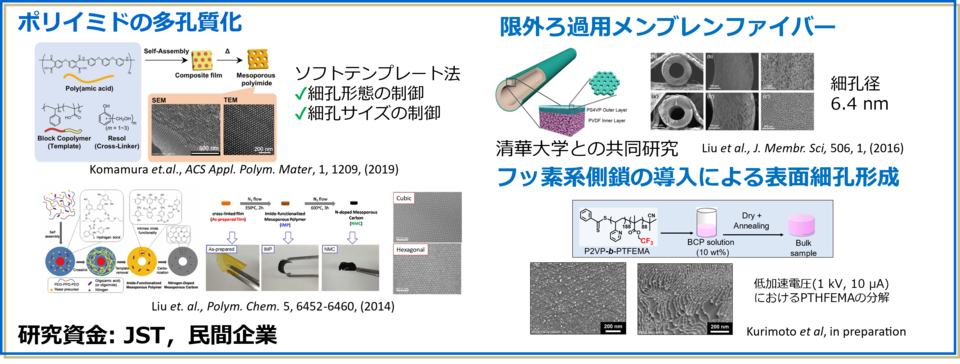

Research 3. Creation of Porous Materials Utilizing Microphase Separation of Block Copolymers

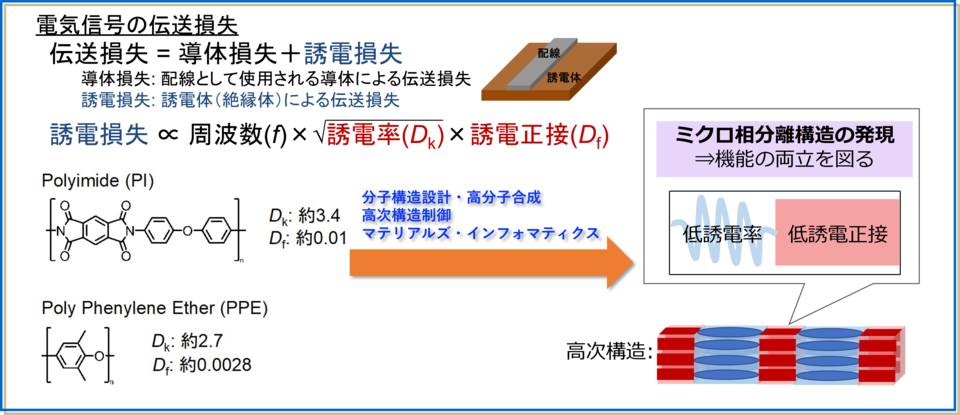

Research 4. Development of Low Dielectric Loss Materials

Research 5. Materials Informatics Utilizing Deep Learning and Robotics

Materials informatics, which advances materials research from the perspective of data science, is gaining attention as a methodology for creating new materials. At its core are computational techniques, including artificial intelligence (AI), which are used to predict and propose materials, as well as robotic systems to control experimental processes. To achieve chemical research with AI robots that possess the rich knowledge, advanced decision-making skills, and refined techniques of veteran scientists, large-scale language models (foundation models), deep learning, and autonomously constructed automated experimental equipment are being integrated. This enables the construction of systems from scratch for applications such as polymer synthesis.

生成AIの化学研究への適用可能性検証 東工大が実験の効率化や成功確率の向上へ

電波新聞 2023年11月17日 新聞・雑誌

東⼯⼤、「GPT-4」連動ロボで化学実験 研究に⽣成AI

日本経済新聞 2023年11月9日 新聞・雑誌

効果的な化学研究 AIがサポート

科学新聞 2023年11月7日 新聞・雑誌

「GPT-4」の化学知識 大学院レベルに相当

日刊工業新聞 2023年10月13日 新聞・雑誌